设备图片结构 Equipment drawing structure

| 设备总图结构 Equipment general drawing structure

|

▼工艺结构组成: Process structure composition

• 本机主要由防爆装置、电控系统、光电检测、称重装置、灌装装置等部分组成。

• 电器控制部分则由PLC可编程逻辑程序控制器,集成度高,控制能力强,运行可靠,使机器的操作更简单、方便。

2.1. This machine is mainly composed of explosion-proof device, electric control system, photoelectric detection, weighing device, filling device, etc.

2.2. The electrical control part is controlled by PLC programmable logic program controller, which has high integration, strong control ability and reliable operation, which makes the operation of the machine simpler and more convenient. The photoelectric sensors are all advanced sensing elements, so that the mechanical and electrical integration of the machine has a perfect performance.

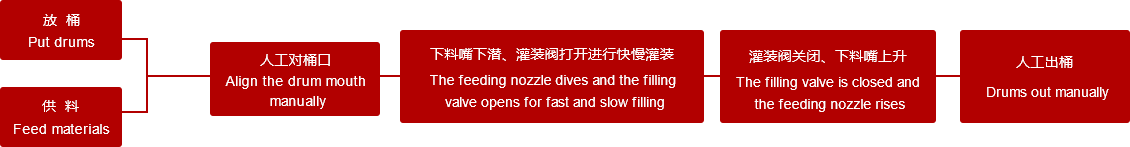

▼包装工艺流程: Brief description of packaging principle

▼充填过程: Filling process

人工将空桶放置到称重称台上 ,人工进行桶口对位,点击启动按钮,下料嘴的气缸会进行下潜,当下料嘴下潜到最低点后自动去皮、灌装等一系列动作,灌装计量达到完成后,下料嘴上升,灌装结束。

▼Describe:

Manually place the empty drum on the weighing platform, manually align the drum mouth, click the start button, and the cylinder of the feeding nozzle will dive. When the feeding nozzle reaches the lowest point, it will automatically peel and fill. After a series of actions, after the filling measurement is completed, the feeding nozzle rises and the filling ends.

截屏,微信识别二维码