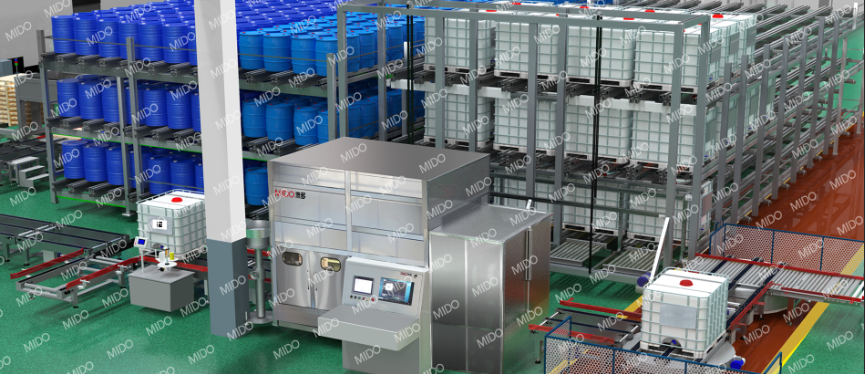

▼设备概述 / Equipment overview:

本机针对防爆环境内200L桶的液体包装而设计的智能化包装系统,用于200L桶(含托盘)的包装。采用视觉寻口,能够实现200L桶的自动开盖、自动下潜、自动快慢速灌装、自动接漏、自动封螺纹盖等流程自动化的包装。 |  |

灌装主机部分采用环保外框,可视窗,进出桶自动升降移门,灌装时可形成封闭空间。本机电气控制部分由PLC可编程控制器、称重模块、视觉系统等组成,控制能力强,自动化程度高。PLC设有以太网通讯接口,可与业主系统进行通讯。本机具备无桶不灌装,对不准桶口不灌装等功能,避免了物料的浪费和污染,使机器的机电一体化得到了很好的表现。

利用称重的工作原理来实现灌装量的控制。灌装时通过可编程控制器PLC控制灌装阀打开的时间,物料自行流入(或通过泵供料输送)待装容器中去。本机灌装部通过手动阀门+双道快慢灌装气动球阀,以及灌装枪头双行程开关,实现灌装流速控制。在灌装时,即可实现先快灌,后慢灌的动作,也可实现先慢灌,中途快灌,最后漫灌的灌装动作,灌装结束后进行自动螺纹盖旋盖和防水盖封盖动作。

|

▼Describe:

This machine is an intelligent packaging system specially designed for liquid packaging in 200L drums in an explosionproof environment. It is used for packaging 200L drums (including trays). Using visual port search, it can realize automatic packaging of 200L drums such as automatic opening, automatic diving, automatic fast and slow filling, automatic leakage, and automatic screw cap sealing.

The main machine part of the filling adopts an environmentally friendly outer frame, with windows, automatic lifting and sliding doors in and out of the drums, which can form a closed space during filling. The electrical control part of this machine is composed of PLC programmable controller, weighing module, vision system, etc., with strong control ability and high degree of automation. The PLC has an Ethernet communication interface to communicate with the owner's system. This machine has the functions of no drum no filling, no drum mouth no filling, etc., which avoids the waste and pollution of materials and makes the mechanical and electrical integration of the machine perfect.

The working principle of weighing is used to realize the control of filling volume. When filling, the programmable controller PLC controls the opening time of the filling valve, and the material flows into the container to be filled by itself (or feed through the pump). The filling department of this machine realizes the control of the filling flow rate through the manual valve + dual channel fast and slow filling pneumatic ball valve, and the filling gun head double stroke switch. During filling, the action of fast filling first, then slow filling can be realized, and the filling action of first slow filling, fast filling in the middle, and finally flood filling can be realized until the final set overall filling volume. After filling, the automatic screw cap screwing and waterproof cap sealing actions are performed.

This equipment has a weighing and feedback system, which can set the filling volume and micro-adjust the fast and slow filling volume.It has a double weighing platform weight recheck function, which is used to recheck the filling weight after filling.The touch screen can display the current time, equipment operating status, filling weight, accumulated output and other functions at the same time.The filling line has a full line interlocking protection function, filling automatically stops when the drum is missing, and automatically resumes filling when the drum is in place.

The machine is equipped with a complete machine cover, a door that automatically opens and closes on one side of the drum in and out of the drum, automatically opens and closes when entering and leaving the drum, and remains closed during filling. The rest is a closed structure, with windows, and a VOC discharge interface for connecting to the owner's VOC draft system, and the packaging equipment maintains a negative pressure.

▼自动化控制系统 / Automation Control System 控制系统由触摸屏、PLC、工控机组成,具有系统自检、故障显示报警并显示个设备状态、精度、速度、产量等功能,各系统自带人机界面,所有参数均可在人机界面上操作。提供详细的流水线控制过程流程图和逻辑图。可储存灌装物料种类,数量批次、日期、每桶重量、保存时长等记录功能。 |

|

▼Describe:

The control system is composed of touch screen, PLC, and industrial computer. It has the functions of system selfcheck, fault display and alarm, and display of equipment status, accuracy, speed, output, etc. Each system as its own manmachine interface, and all parameters can be on the manmachine interface operating. Provide detailed flow chart and logic diagram of pipeline control process.It can store the types of filling materials, quantity batch, date, weight of each barrel, storage time and other recording functions.

▼灌装系统及开旋盖系统 / Filling system and capping system

桶口定位由视觉相机拍摄桶口后输出桶口XY轴定位坐标参数,伺服电机驱动灌装枪头移动至桶口后自动下潜至桶内灌装,灌装时枪头随液位上升而自动上升。灌装枪头为中空设计,并可对枪头关闭后物料挂丝进行吹扫,防止物料飞溅。灌装枪头下部设有接液盘,在灌装结束后,灌装头上升后接漏盘伸出,防止物料污染包装物和输送线体。接液盘为徒手拆卸设计,无需工具即可拆卸,方便清理。本机设计有粗细两套枪头以及旋盖装置,用于针对不同物料粘度的不同桶型。两种不同枪头和旋盖头通过预设的程序根据不同桶型自动切换。

▼Describe:

The drum mouth positioning is captured by the vision camera and output the barrel mouth XY axis positioning coordinate parameters. The servo motor drives the filling nozzle head to move to the drum mouth and then automatically descends into the drum for filling. During filling, the nozzle head changes as the liquid level rises. Automatically rise. The filling gun head is hollow design, and it can blow the material hanging wire after the gun head is closed to prevent material splashing.The bottom of the filling head is equipped with a liquid receiving tray. After the filling is completed, the filling head rises and the leakage tray extends to prevent the material from contaminating the packaging and the conveying line. The wetted tray is designed to be disassembled by hand, which can be disassembled without tools for easy cleaning.

This machine is designed with two sets of heads and screw capping devices, which are used for different drums with different viscosity of materials. Two different heads and capping heads are automatically switched according to different drum types through a preset program.

Cap Screwing Department: Using the company's patented technology, it can pack the vertical of the capping head and the barrel surface, and can open and screw the cap smoothly and easily, without damaging the cap, not damaging the cap, and sealing tightly. The waterproof cover is manually placed in the lid storage device, and the waterproof cover head sucks the waterproof cover released from the lid storage device and presses it to the barrel mouth. The cap capacity of the cap storage device is not less than 50 caps per kind.Due to site reasons, the size of the equipment should be as compact as possible. After manual opening and inspection, the drum mouth needs to be placed toward the center of the tray, and the position of the barrel mouth does not exceed ±30° of the diagonal line of the tray.

▼触摸屏及称重系统 / Touch screen and weighing system

物料灌装参数设置及操作通过触摸屏操作,简洁直观,并具有温度显示,故障诊断报警、提示功能。具有记忆存储程序功能,能够存储多组参数,能够查看历史数据。能够自动统计计算计量偏差,且可为不同程序命名,更换不同规格或变换生产能力,只需调整不同的参数,能够提高工作效率。

▼Describe:

The material filling parameter setting and operation are operated through the touch screen, which is simple and intuitive, and has the functions of temperature display, fault diagnosis, alarm and prompt. It has the memory storage program function, can store multiple sets of parameters, and can view historical data. It can automatically calculate the measurement deviation, and can name different programs, change different specifications or change production capacity, and only need to adjust different parameters, which can improve work efficiency. The weighing system adopts famous American brand sensors to ensure filling accuracy. In addition, the system has oil-proof protection function, and the sensor is easy to install, disassemble and repair.

The weighing platform has a protection function. When the head is topped with the drum, the head automatically returns. And there is the longest filling time protection.

▼视觉定位系统 / Visual positioning system

视觉:采用工业智能相机,装入可视型隔爆机箱内工作。由智能相机测出桶口坐标位置参数,PLC控制坐标移动系统将灌装枪对准桶口。三维坐标移动系统:采用导轨系统和防爆减速电机。

Vision: Industrial smart camera is used, and it works in a visual flameproof case. The smart camera measures the coordinate position parameters of the drum mouth, and the PLC controls the coordinate movement system to aim the filling head at the drum mouth. Threedimensional coordinate movement system: adopts guide rail system and explosion-proof geared motor.

|

|

▼Describe:

Automatic mouth search: visual positioning, coordinate movement system to find the mouth, the filling head descends to fill.Fast and slow dual-speed automatic quantitative filling: to ensure filling accuracy and production capacity;Filling form: filling on the liquid surface or below the liquid surface;The pneumatic bottom valve is always open, and the front-end flow limit is increased slowly-slowing down the flow rate of the filling gun outlet;The design of the liquid contact cup-to minimize the leakage of residual liquid when the filling is completed;

The automatic and manual modes of quantitative filling can be selected-convenient operation and maintenance;Automatic peeling function-overcomes the influence of the inconsistent weight of the filling container on the accuracy;The fixed value point can be adjusted-suitable for quantitative filling of various weight ranges;Automatic diagnosis, fault warning-improve the reliability of system work;Safety interlock-the barrel is in place, the spray head is put down; the top drum of the filling gun is returned;Self-locking control-before filling, filling is allowed after detecting that the spray head is in place;

Product setting storage-can store up to a variety of different product weight settings and related perfusion parameters;Tolerance detection-automatic detection of full filling error;Touch screen-Chinese operation interface, intuitive prompts and convenient settings.Alarm prompt-accurate to the point of failure.

主要技术参数 / Main technical parameters | |

防爆类型 / Explosion-proof type | Exd ii BT4 |

接触物料材质 / Contact material material | PTFE+304不锈钢。/ PTFE+304 stainless steel |

软管 / Hose | 工作压力14bar / working pressure 14bar |

温度范围 / Temperature range | -20℃~+160°℃ |

材质 / Material | PVC涂布织物外皮,内衬PTFE+不锈钢丝 / PVC coated fabric outer skin, lining PTFE+stainless steel wire |

外形尺寸(长×宽×高)mm / Dimensions (length×width×height) mm | 3300×2400×3600 |

适用桶型 / Applicable drum type | 200L桶(4桶/托盘)/ 200L drum (4 drums/pallet) |

称重范围 / Weighing range | 0-1500kg |

分度值 / Graduation value | 50g |

电源功率 / Power supply | AC380V/50Hz;10kW |

需配气源 / Need to be equipped with air source | 0.4-0.6MPa;1.5m³/h |

接口 / Interface | φ12软管 / φ12 hose |

截屏,微信识别二维码